Basic Info.

Model NO.

YLC-5000AC

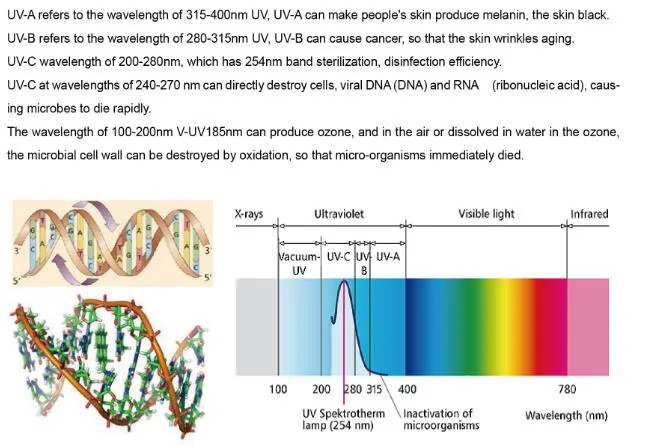

UV Light

UV-C 254nm Wavelength

Tube

Quartz Tube

Water Inlet Hardness

Less Than 120mg/Liter

Water Inlet Turbidity

Less Than 1 Ntu

Water Inlet Iron Content

Less Than 0.3 Mg/Liter

Water Inlet Manganese Content

Less Than 0.05 Mg/Liter

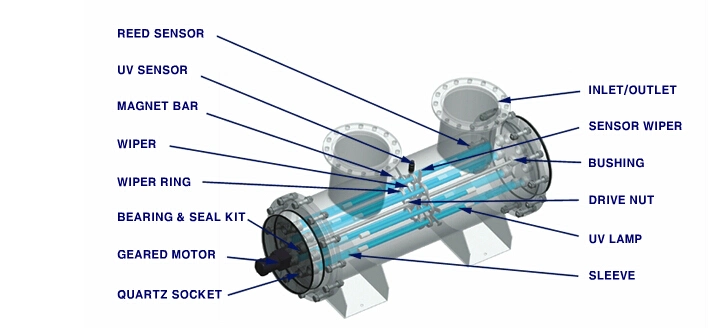

Cleaning Model

Hand-Cleaning, Rod Cleaning, Automatic Motor

Lifespan of UV Lamp

9000 to 12000 Hours

Control System

Control Box, PLC, Remote Control, etc

UV Lamps Power Model

40W,80W,120W,150W,320W

Transport Package

Plywood Case Into Container

Specification

refer to parameters sheet or to be customized

Trademark

YLD

Origin

Jiangyin, China

HS Code

8543709990

Production Capacity

100 Sets Per Month

Product Description

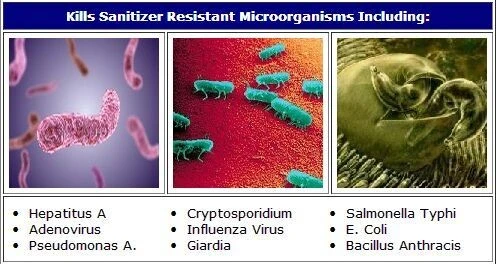

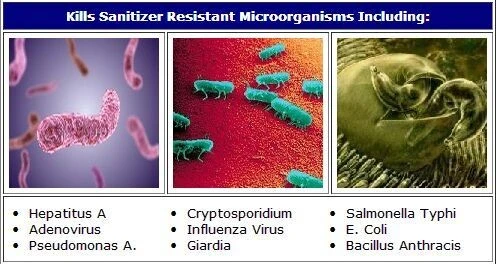

UV water treatment systems (UV sterilizers) kill bacteria in water. They are often used to ensure safe drinking water from well, spring and borehole water supplies. Due to increased legislation are now regularly used in food and drink related industries.

Micro organisms including bacteria, viruses and cysts are all around us naturally. Many are harmless but exposure to "bad" ones can cause severe illness particularly in the elderly and very young. There is a wide variety of water treatment products available to improve taste, clarity, scale etc but none of these are designed to combat bacteria. Ultra violet water treatment is one of the safest ways to disinfect water as the UV rays are a natural component of sunlight. No chemicals are added so there is no danger from overdosing or creating a bad taste.

What does a UV sterilizer do?

A UV sterilizer is used to control infections by stopping the spread of microorganisms from one fish/coral/invertebrate to another through the water. It is also used in pond applications to control free-floating algae. When operated correctly, free-floating microorganisms will be killed by the UV light. Note that the organisms must be in the water that flows to the UV sterilizer. The UV light has no residual effect and will not kill organisms attached to fish (e.g., adult stage of ich) or rocks (e.g., algae).

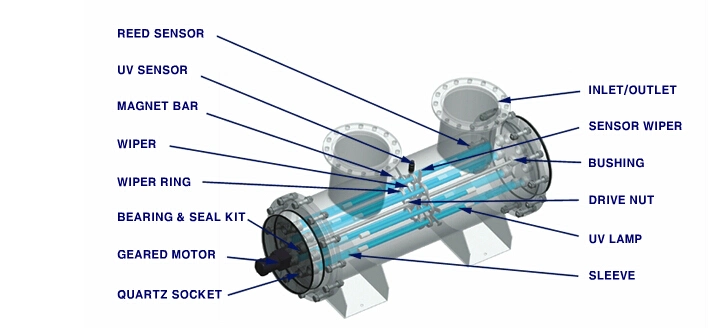

How do UV sterilizers work?

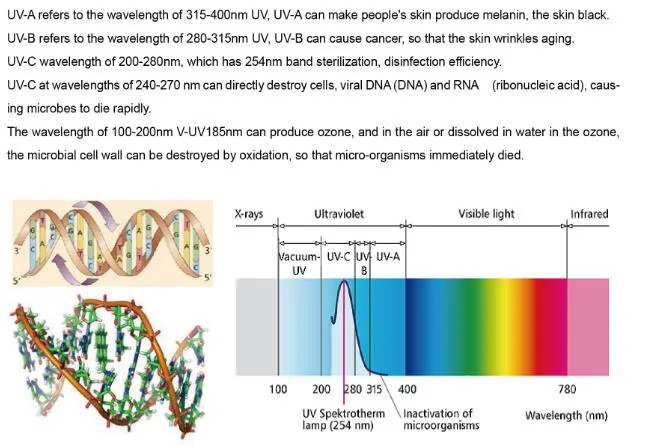

The UV sterilizer utilizes a germicidal fluorescent lamp that produces light at a wavelength of approximately 254 nanometers (2537 Angstroms). The water with the bacteria/algae passes over the bulb (or around the bulb if a quartz sleeve is used) and is irradiated with this wavelength. As the light penetrates the bacteria/algae, it mutates the DNA (genetic material), preventing growth/multiplication of the organism.

UV Systems are used in many applications

UV Systems are commonly used for water disinfection / sterilization of drinking water and process water on a wide range of water sources, by state governments, municipal councils, outback water supplies, mining industry, manufacturing industry, food, dairy, aquaculture, indoor swimming pools, pharmaceutical manufacture, laboratories, research centres, wine and brewing industries and in thousands of domestic, commercial and industrial applications to ensure that the water is biologically pure and free from bacteria and pathogens.

Operators of business and facilities supplying water from private sources have a responsibility to ensure that their water complies with Drinking Water Standards.

1.caravan parks, camping grounds

2.guest houses, backpackers accommodations, farm stays, bed and breakfast accommodations

3.motels and hotels

4.petrol stations, roadhouses

5.community halls and conference centers

6.recreational and sporting facilities

7.schools

8.food and beverage manufacturing premises

9.cafes, restaurants, market stalls, rural food premises, marinas

10.mines and work site

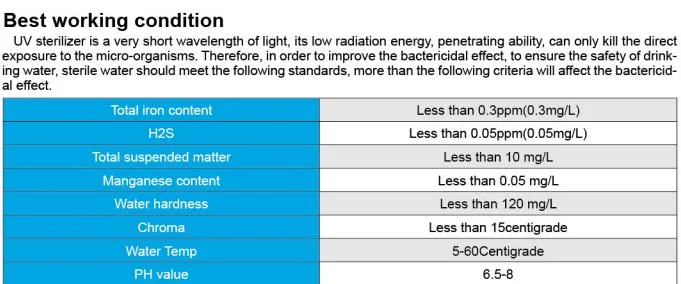

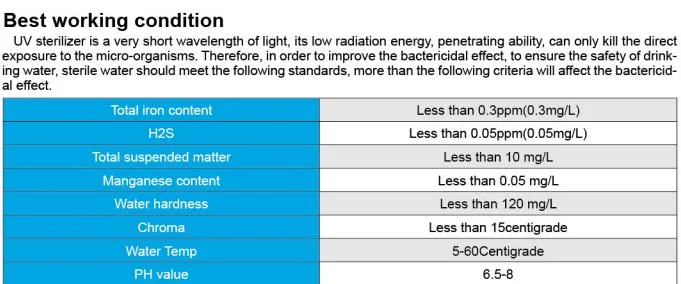

Water Quality (in)

Water quality plays a major role in the transmission of germicidal UV rays. It is recommended that the water does not exceed following maximum concentration levels

Effectively treating water with higher concentration levels than listed above can be accomplished, but may require added measures to improve water quality to treatable levels. If, for any reason, it is believed the UV transmission is not satisfactory, contact the factory.

UV wavelength (nm)

DOSAGE is the product of intensity & time

dosage=intensity*time=micro watt/cm2*time=microwatt-seconds per square centimeter

(μW-s/cm2)

Note:1000μW-s/cm2=1mj/cm2(milli-joule/cm2)

Facts you should know

Chloramines (residual chlorine) is the smell you get from chlorine

Chloramines is the cause of eye and skin irritation

Chloramines is the cause of composite building structure corrosion.

No microbe can immunize it's self against UV rays even those pathogens that cannot be killed by chlorination.

The adverse impact of pool chemicals, especially to children, is 5 times greater than passive smoking Product and installation costs of Ultraviolet water sterilisation reactors will depending on pool size and site location.

Micro organisms including bacteria, viruses and cysts are all around us naturally. Many are harmless but exposure to "bad" ones can cause severe illness particularly in the elderly and very young. There is a wide variety of water treatment products available to improve taste, clarity, scale etc but none of these are designed to combat bacteria. Ultra violet water treatment is one of the safest ways to disinfect water as the UV rays are a natural component of sunlight. No chemicals are added so there is no danger from overdosing or creating a bad taste.

What does a UV sterilizer do?

A UV sterilizer is used to control infections by stopping the spread of microorganisms from one fish/coral/invertebrate to another through the water. It is also used in pond applications to control free-floating algae. When operated correctly, free-floating microorganisms will be killed by the UV light. Note that the organisms must be in the water that flows to the UV sterilizer. The UV light has no residual effect and will not kill organisms attached to fish (e.g., adult stage of ich) or rocks (e.g., algae).

How do UV sterilizers work?

The UV sterilizer utilizes a germicidal fluorescent lamp that produces light at a wavelength of approximately 254 nanometers (2537 Angstroms). The water with the bacteria/algae passes over the bulb (or around the bulb if a quartz sleeve is used) and is irradiated with this wavelength. As the light penetrates the bacteria/algae, it mutates the DNA (genetic material), preventing growth/multiplication of the organism.

UV Systems are used in many applications

UV Systems are commonly used for water disinfection / sterilization of drinking water and process water on a wide range of water sources, by state governments, municipal councils, outback water supplies, mining industry, manufacturing industry, food, dairy, aquaculture, indoor swimming pools, pharmaceutical manufacture, laboratories, research centres, wine and brewing industries and in thousands of domestic, commercial and industrial applications to ensure that the water is biologically pure and free from bacteria and pathogens.

Operators of business and facilities supplying water from private sources have a responsibility to ensure that their water complies with Drinking Water Standards.

1.caravan parks, camping grounds

2.guest houses, backpackers accommodations, farm stays, bed and breakfast accommodations

3.motels and hotels

4.petrol stations, roadhouses

5.community halls and conference centers

6.recreational and sporting facilities

7.schools

8.food and beverage manufacturing premises

9.cafes, restaurants, market stalls, rural food premises, marinas

10.mines and work site

Water Quality (in)

Water quality plays a major role in the transmission of germicidal UV rays. It is recommended that the water does not exceed following maximum concentration levels

Effectively treating water with higher concentration levels than listed above can be accomplished, but may require added measures to improve water quality to treatable levels. If, for any reason, it is believed the UV transmission is not satisfactory, contact the factory.

UV wavelength (nm)

DOSAGE is the product of intensity & time

dosage=intensity*time=micro watt/cm2*time=microwatt-seconds per square centimeter

(μW-s/cm2)

Note:1000μW-s/cm2=1mj/cm2(milli-joule/cm2)

| model | capacity | Power | inlet-outlet | reactor | panel | Anchor | G weight |

| m³/hour | watt | mm | L×W×H | cm | screw | Kg | |

| YLCn-005 | 0.3 | 16 | 1/2″ | 30×6×11 | without | without | 5 |

| YLCn-008 | 1 | 25 | 1/2″ | 47×6.3×11 | without | without | 10 |

| YLCn-050 | 2 | 40 | 1″ | 100×9×20 | Φ8.9×25 (d×L) | 69×4×Φ1 | 25 |

| YLCn-150 | 6 | 80 | 1+1/4″ | 100×11×23 | 69×4×Φ1 | 30 | |

| YLCn-200 | 8 | 120 | 1+1/2″ | 100×15.9×30 | Φ8.9×45 (d×L) | 69×7×Φ1 | 35 |

| YLCn-300 | 12 | 160 | 2″ | 100×15.9×32 | 69×7×Φ1 | 40 | |

| YLC-050 | 2 | 40 | DN25/1″ | 100×8.9×30 | 25×30×12 (W×H×D) | 60×4×Φ1 | 45 |

| YLC-150 | 6 | 80 | DN32/11/4″ | 100×10.8×30 | 60×4×Φ1 | 50 | |

| YLC-200 | 8 | 120 | DN40/11/2″ | 100×15.9×40 | 60×7×Φ1 | 60 | |

| YLC-300 | 12 | 160 | DN50/2″ | 100×15.9×40 | 60×7×Φ1 | 70 | |

| YLC-360 | 15 | 200 | DN65/21/2″ | 100×15.9×40 | 60×7×Φ1 | 120 | |

| YLC-500 | 20 | 240 | DN65/21/2″ | 100×21.9×50 | 60×11×Φ1.2 | 130 | |

| YLC-600 | 25 | 280 | DN80/3″ | 100×21.9×50 | 60×11×Φ1.2 | 140 | |

| YLC-700 | 30 | 320 | DN100/4″ | 100×21.9×50 | 60×11×Φ1.2 | 150 | |

| YLC-1000 | 40 | 360 | DN100/4″ | 100×21.9×50 | 60×11×Φ1.2 | 160 | |

| YLC-1200 | 50 | 400 | DN125/5″ | 100×21.9×50 | 60×11×Φ1.2 | 180 | |

| YLC-1500 | 60 | 420 | DN150/6″ | 170×27.3×57 | 120×16×Φ1.4 | 210 | |

| YLC-2000 | 80 | 560 | DN150/6″ | 170×27.3×57 | 120×16×Φ1.4 | 220 | |

| YLC-2500 | 100 | 700 | DN150/6″ | 170×27.3×57 | 60×128×30 (W×H×D) | 120×16×Φ1.4 | 275 |

| YLC-3000 | 125 | 840 | DN150/6″ | 170×27.3×57 | 120×16×Φ1.4 | 300 | |

| YLC-4000 | 150 | 1120 | DN200/8″ | 173×32.5×65 | 120×20×Φ1.6 | 325 | |

| YLC-5000 | 200 | 1400 | DN200/8″ | 173×37.7×72 | 120×22×Φ1.6 | 350 | |

| YLC-7000 | 300 | 2100 | DN250/10″ | 175×42.6×80 | 120×24×Φ2.0 | 400 | |

| YLC-10K | 400 | 2520 | DN250/10″ | 176×52.9×95 | 60×150×40 (W×H×D) | 120×22×Φ2.2 | 475 |

| YLC-15K | 600 | 3080 | DN300/12″ | 176×78×110 | 120×32×Φ2.4 | 600 | |

| YLC-20K | 800 | 3920 | DN350/14″ | Designated | Designated | Designated | Designated |

| YLC-25K | 1000 | 4760 | DN350/14″ | Designated | Designated | Designated | Designated |

Chloramines (residual chlorine) is the smell you get from chlorine

Chloramines is the cause of eye and skin irritation

Chloramines is the cause of composite building structure corrosion.

No microbe can immunize it's self against UV rays even those pathogens that cannot be killed by chlorination.

The adverse impact of pool chemicals, especially to children, is 5 times greater than passive smoking Product and installation costs of Ultraviolet water sterilisation reactors will depending on pool size and site location.